Researchers on the College of Ottawa have recognized elements that affect the standard and complexity of 3D-printed meals. Printed in Physics of Fluids, the examine highlights the significance of contemplating these elements for higher high quality, management, and effectivity in additive manufacturing of edible supplies. This might probably assist deal with world meals provide and diet challenges.

Researchers establish elements affecting the standard of edible supplies produced by additive manufacturing.

3D-printing meals may deal with world challenges in meals provide and diet. However there are hurdles concerned in adapting additive manufacturing to provide edible supplies.

InPhysics of Fluids, from AIP Publishing, College of Ottawa researchers Ezgi Pulatsu and Chibuike Udenigwe establish a spread of things that have an effect on the print high quality and form complexity of meals created with additive manufacturing. Accounting for these options can enhance meals high quality, enhance management, and velocity up printing.

Additive manufacturing of meals includes designing (3D shapes and their geometric codes), pre-processing (meals ink preparation), manufacturing (deposition of layers to create shapes), and post-processing (baking, boiling, cooking, freezing, frying, or drying). Every step is a chance to create progressive meals.

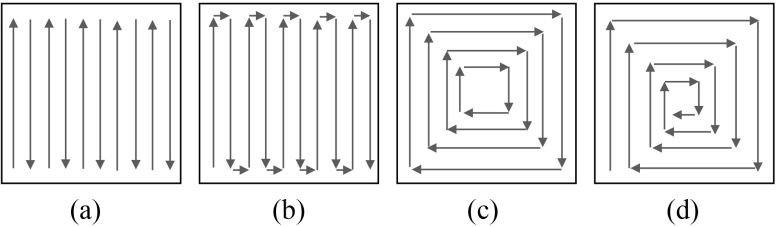

Altering the printing patterns and substances of the preliminary combine or paste can have an effect on the meals’s matrix and microstructures and subsequently its texture.

The circulate of that blend in additive manufacturing can also be essential and is typically inspired or discouraged by controlling substances and course of circumstances.

Widespread toolpath patterns utilized in additive manufacturing applied sciences: a) raster, b) zigzag, c) contour, and d) spiral. Credit score: Ezgi Pulatsu and Chibuike Udenigwe

“Extrusion-based 3D printing is probably the most relevant approach for meals,” stated Pulatsu. “It includes a syringe loaded with a meals paste – similar to puree, dough, or frosting – being pressured out of a nozzle by direct (pushing the plunger) or oblique pressure (compressed air).”

Making a steady steady circulate is step one to profitable printing, so designed shapes might be produced by layering stringlike materials in a managed approach.

“As soon as a layer is deposited, we not need it to circulate; in any other case, it's going to destroy the form we created,” stated Pulatsu.

Submit-processing – by way of baking, boiling, cooking, freezing, frying, or drying – bodily and chemically transforms the meals’s micro- and macromolecules and results in varied textures and tastes. On the similar time, the form ought to be conserved or rigorously managed.

“We additionally produce other mechanisms of making meals constructions through totally different 3D-printing methods,” Pulatsu stated. “For instance, materials jetting makes use of liquid binders deposited on powder to kind self-supporting layers, and liquid inks that harden after deposition can be used.”

One solution to make additive manufacturing extra environment friendly for the meals trade is by establishing a printing path (a collection of computer-controlled actions), which is usually skipped for meals functions.

“Future research ought to discover the fee effectivity of various applied sciences when it comes to construct time, the place form complexity and toolpath methods – which contain the printing path, transferring head velocity, and nonprinting actions – are additionally thought-about,” stated Pulatsu. “Meals is important to residing, and it’s turning into extra crucial as a result of rising world inhabitants and environmental modifications. Due to this fact, novel meals and matrices ought to be designed in session with cooks, meals scientists, and engineers, and in keeping with present wants.”

Reference: “Views, analyses, and progress in additive manufacturing of meals” by Ezgi Pulatsu and Chibuike Udenigwe, 21 March 2023, Physics of Fluids.

DOI: 10.1063/5.0137328

Post a Comment