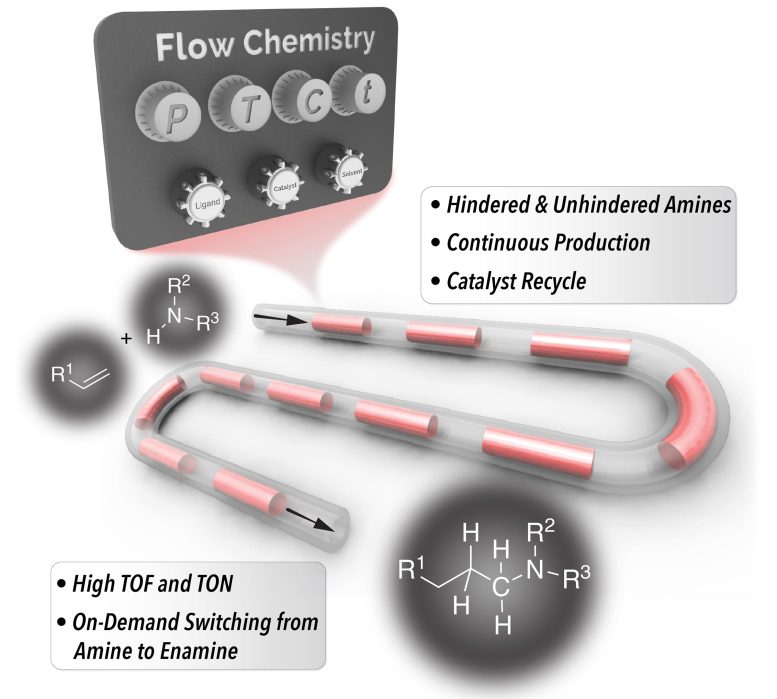

Researchers at North Carolina State College have developed a sooner, inexpensive approach for producing hindered amines – a category of chemical substances used as constructing blocks in merchandise starting from prescription drugs and agrochemicals to detergents and natural light-emitting diodes. The success of the brand new approach is made potential by two issues. First, by utilizing a steady stream reactor that permits for steady stream of each gases and liquids in a segmented stream format, the researchers have been in a position to make the kinetics of the response much more environment friendly. Second, the brand new approach makes use of a co-catalyst – fluorinated benzoic acid – which reduces the quantity of vitality wanted to carry out a few of the needed reactions within the course of. Credit score: Milad Abolhasani, NC State College

Researchers at North Carolina State College have developed a sooner, inexpensive approach for producing hindered amines – a category of chemical substances used as constructing blocks in merchandise starting from prescription drugs and agrochemicals to detergents and natural light-emitting diodes.

“Hindered amines are utilized in an incredible number of merchandise, however the entire current strategies for producing these amines are sophisticated and costly,” says Milad Abolhasani, corresponding writer of a paper on the brand new approach and an affiliate professor of chemical and biomolecular engineering at NC State. “We got down to develop a greater technique for synthesizing these hindered amines, and we have been profitable.”

One of many inexpensive strategies for producing hindered amines is hydroaminomethylation, or HAM. Nevertheless, the chemical trade has largely prevented utilizing HAM, as a result of there are too some ways issues can go fallacious – leaving producers with undesirable chemical substances as a substitute of the functionalized amines they have been attempting to make. Researchers have improved the HAM course of through the years. However the entire strategies for avoiding undesirable byproducts have meant extending the timeframe of the HAM course of, in order that it takes hours to carry out the entire needed reactions. Till now.

“We’ve developed a HAM approach that makes use of steady stream reactor applied sciences to provide hindered amines extra effectively,” Abolhasani says. “Our HAM course of takes lower than half-hour usually. The one merchandise are hindered amines and water. And we're in a position to recycle the first catalyst, rhodium/N-Xantphos, which additional drives down prices.”

The success of the brand new approach is made potential by two issues. First, by utilizing a steady stream reactor that permits for steady stream of each gases and liquids in a segmented stream format, the researchers have been in a position to make the kinetics of the response much more environment friendly. Second, the brand new approach makes use of a co-catalyst – fluorinated benzoic acid – which reduces the quantity of vitality wanted to carry out a few of the needed reactions within the HAM course of.

Finally, this method drives down the price of producing hindered amines utilizing cheap feedstock, permitting customers to provide them extra shortly and with no poisonous byproducts.

“By designing a cooperative catalyst system, we’ve demonstrated that the speed of the HAM reactions in our system will be 70 occasions increased than the prevailing state-of-the-art processes,” says Malek Ibrahim, first writer of the paper and a former postdoctoral researcher at NC State. “This course of can be a great instance for the way stream chemistry platforms can enhance catalyst turnover frequency, which is more and more essential as the value of rhodium catalysts goes up.”

The brand new approach is especially enticing for decentralized manufacturing operations, because the small footprint of the required tools and its scalability permits customers to effectively produce hindered amines on-site and on-demand.

“What’s extra, the identical approach may also be used to provide enamines – that are different chemical constructing blocks – on demand, just by tuning the solvents we use within the stream reactor,” Ibrahim says. “You possibly can actually swap backwards and forwards between producing amines and enamines with out having to cease the manufacturing course of, because the solely factor you’re altering is the solvent combination.”

The researchers have filed a provisional patent on the brand new approach and are actually on the lookout for industrial companions to place the approach into widespread use.

The analysis paper can be revealed on Could 4, 2022, within the journal Nature Communications. The work was achieved with start-up funding from NC State.

Reference: “Recyclable Cooperative Catalyst for Accelerated Hydroaminomethylation of Hindered Amines in a Steady Segmented Circulate Reactor” 4 Could 2022, Nature Communications.

DOI: 10.1038/s41467-022-30175-0

Post a Comment