3D filament printers can produce something from vacation ornaments to medical implants, so there’s no scarcity of pleasure within the course of. The issue is getting out of your 3D mannequin to the precise print. A number of issues can go flawed and break your print, particularly in case you’re new to this and nonetheless determining how 3D printing works.

On this article, we’ll present you tips on how to get higher outcomes by serving to you repair your 3D filament prints gone awry. Verify all our troubleshooting ideas, apply them step-by-step, and above all, be affected person. 3D FDMprinting may be irritating at instances, but it surely’s rewarding resulting from its numerous real-world functions.

It’s Not Printing

Is your 3D printer failing to print something? Don’t fear, it is a widespread problem. There are fairly a couple of issues that may forestall your printer from extruding any materials. Listed here are the most typical points and tips on how to troubleshoot them.

1. Verify the Filament

You’ve ready the printer and your mannequin however nothing is occurring. You may even get some residual filament coming via the nozzle, however your mannequin isn’t being printed.

Your printer has run out of filament. This may increasingly sound like an apparent downside, but it surely’s simple to overlook in case you don’t have a printer that warns you when you'll want to add a brand new spool. Earlier than wanting into different doable points, make sure that your 3D printer has loads of filament to print your mannequin.

2. Verify for a Clogged Nozzle

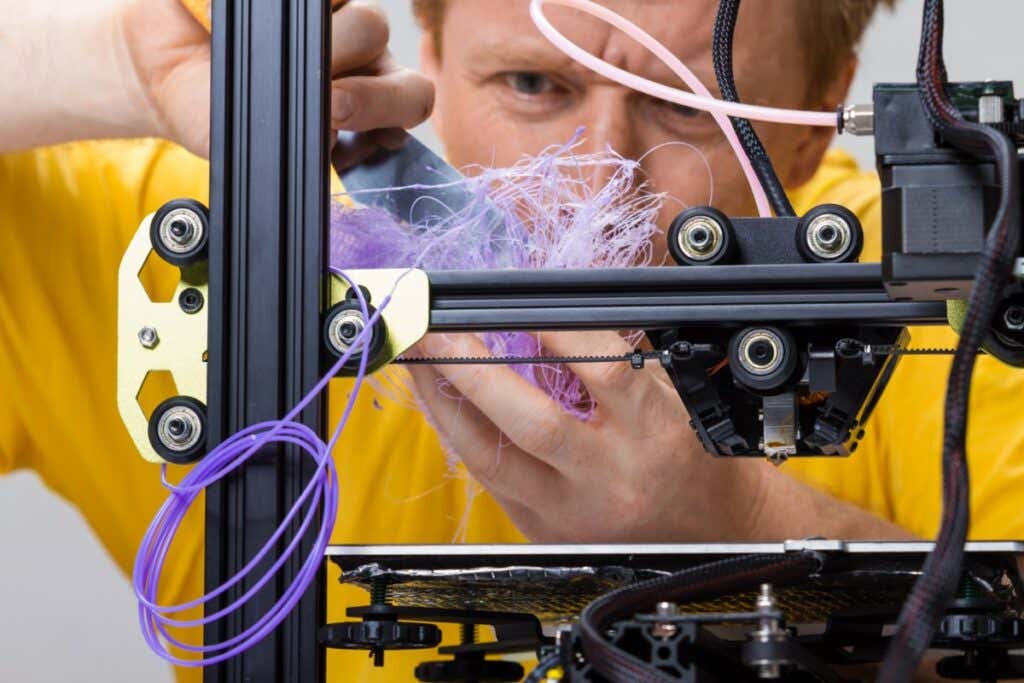

If you happen to’re coping with a clog, nothing will come out of the printer nozzle. This often occurs if you change the filament or the kind of materials and there’s some outdated materials caught within the nozzle. Stop any blockage altogether by performing common upkeep and holding the nozzle clear after each mission.

That mentioned, in case you forgot to wash the nozzle, you may simply take away a clog with the assistance of a needle or another skinny object. Stick the needle via the nozzle to take away as a lot of the remaining filament as doable. You'll be able to warmth the nozzle whereas doing this to make your job simpler.

Alternatively, you may attempt to pressure the brand new filament via to push via the blockage. This won't work by itself and also you’ll have to use some exterior strain to pressure the outdated filament out. If you happen to do this technique, apply pressure gently otherwise you may harm your printer.

3. Regulate the Nozzle

In case your printer nonetheless doesn’t work, the nozzle is perhaps too near the print floor. When that occurs, the filament can’t correctly undergo the nozzle to type layers. This problem can even result in lacking layers, clogs, or adhesion issues, so make sure that to regulate the nozzle top.

Go to the printer’s settings and alter the Z-axis worth. Improve the parameter to what the printer producer recommends within the guide or make gradual changes to the nozzle top till the filament flows usually.

4. Search for Filament Fragmentation

Probably the most widespread 3D printing issues that go unnoticed is filament fragmentation. The filament spool appears high-quality, however nothing comes out via the new finish. On this case, you is perhaps coping with fragmentation someplace between the spool and the nozzle.

This extremely is dependent upon the kind of materials you’re utilizing, whether or not it’s ABS or PLA, and the way outdated it's. That mentioned, the one answer is to take away the filament to search for any broken sections. If the fabric is new however you confirmed that it’s breaking alongside the best way, attempt a distinct spool or attempt decreasing the temperature and movement.

5. Is the Print Head Lacking the Print Mattress?

Did you hear an terrible noise whereas beginning to print? The print head is perhaps attempting to go off its X- or Y-axis and it’s fully off the print mattress. This makes printing unattainable and it’s often attributable to a software program configuration downside.

Be sure you choose the best printer in your slicer software program. Every mannequin comes with its personal settings parameters included in a configuration file. If you choose the flawed mannequin, the print head will probably be misaligned. That mentioned, you also needs to replace the firmware since outdated configurations can even trigger this downside.

The Print Was a Full Failure

So that you managed to get your 3D printer working, however the print turned out to be an entire catastrophe. This often occurs when the print fails to stay or when the helps don’t work as supposed. Regardless of the case, listed below are the most typical 3D printing points.

6. Fixing Horrible Mattress Adhesion

Probably the most widespread issues that trigger prints to fail is the dearth of mattress adhesion. The print fails to stay correctly to the print mattress, so the entire mission turns into a waste of time.

First, make sure that the print mattress is correctly leveled and that it’s clear. Any materials that doesn’t belong on the print floor can forestall the filament from sticking. Afterward, attempt utilizing helps or a brim. Go into your slicer’s settings and print utilizing these extra components.

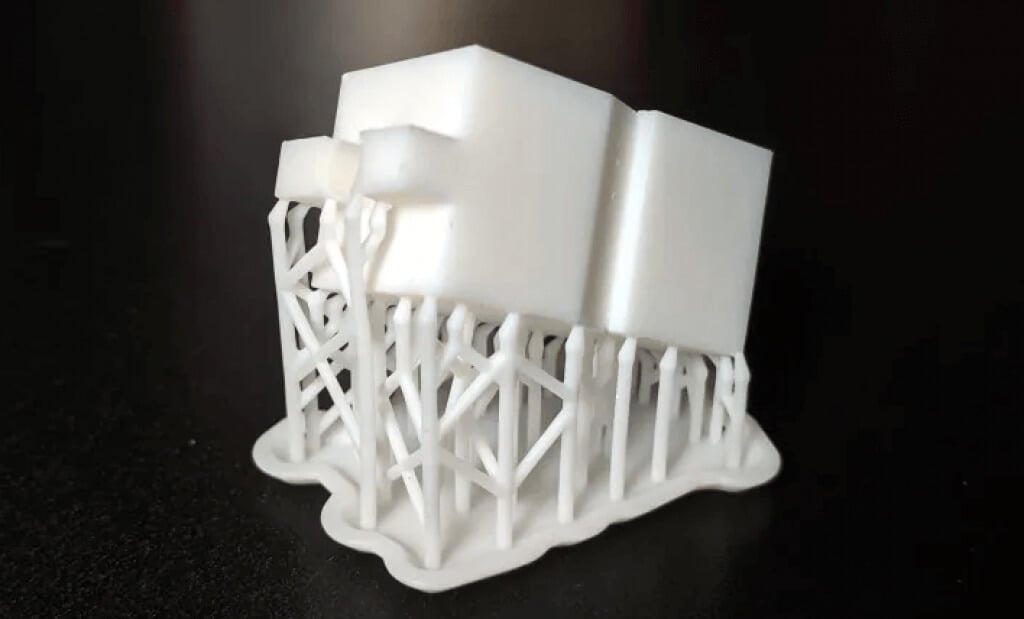

7. Did the Helps Fail and Damage Your Print?

As talked about, utilizing helps might help with print mattress adhesion, however they’re additionally vital when printing advanced fashions. With out helps, your print may be affected by different points like warping edges and layer shifting. Additionally, utilizing the flawed assist kind or not having sufficient helps can break your mission.

Thankfully, your slicer software program ought to robotically generate the helps you want. You then add extra helps manually in case you assume your print is perhaps ruined by overhangs, warping, and different points. That mentioned, you’ll must experiment with helps relying in your mission. There’s no method round this.

8. Extrusion Gone Unhealthy

Typically if you assume you’ve figured the whole lot out, your printer’s scorching finish stops extruding filament midway via the printing course of. This may undoubtedly break your complete mission, but it surely’s simply preventable.

Be sure you have loads of filament. Slicing software program like Cura ought to offer you a tough estimate of how a lot filament you’re going to want in your mission. Simply don’t overlook that materials varieties additionally make a distinction in the case of the estimate, so PLA necessities won't be the identical as ABS necessities. Verify the roll earlier than you get began.

Afterward, examine in case your printer’s nozzle is clogged. This could additionally cease the extrusion out of the blue whereas printing. In that case, consult with our above options for clogged nozzles.

Your Print Seems to be Unhealthy

Regardless of your finest efforts, one thing went flawed and your print doesn’t look as good and clean because it ought to. A number of issues will affect the 3D printing course of and result in warping, stringing, messy layers, random blobs, oozing, unhealthy infill, and ugly negative effects that may break your mission. Right here’s what you are able to do.

9. Repair Warping

Probably the most widespread issues in 3D printing with filament like PLA and ABS is warping. Your mannequin warps its base upwards and it detaches itself from the print mattress. This could additionally lead to cracks, additional rendering your print unusable. Thankfully, there are a number of doable fixes:

- Warmth the print platform. By bringing the temperature of the print mattress near the melting level of the fabric, you may pressure the primary layers to stay completely flat. Regulate the temperature via the slicing software program primarily based on the producer’s suggestions.

- Recalibrate. Undergo the calibration course of and stage the printing mattress. You also needs to regulate the nozzle’s top and ensure it’s not too shut or too removed from the platform.

- Use rafts. If there’s an adhesion or contact downside, attempt including rafts via your slicer software program.

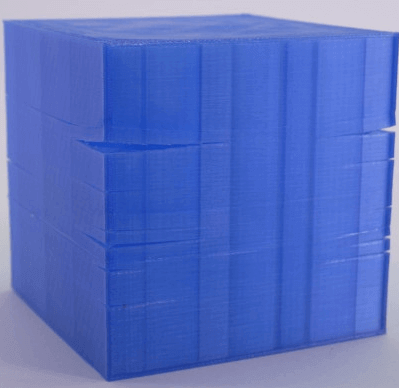

10. Get the First Layer Proper

If one thing goes flawed with the primary layer, chances are high you’ll have an unsightly print. Earlier than you begin printing, make sure that the print mattress is appropriately leveled. An unlevel mattress is a trigger for many failed prints. Afterward, regulate the peak of the nozzle and the movement price.

11. Stop Cracking

There’s nothing uglier and extra ineffective than a cracked print. If the melted plastic cools off too quick, you’ll most likely get some cracks, particularly within the prime layers. Going from such a excessive temperature to a low one will make the fabric contract and that ends in cracks. That is often an issue with massive fashions.

There are two issues you may attempt:

- Regulate the temperature of the extruder. Improve it in small increments whereas not going past the filament producer’s really useful values.

- Regulate the fan velocity. If the cooling fan is blowing too arduous in your mannequin, it is perhaps cooling it too shortly. Tweak it in increments till you discover the candy spot. Bear in mind you continue to want a excessive sufficient fan velocity to stop warping and different deformations.

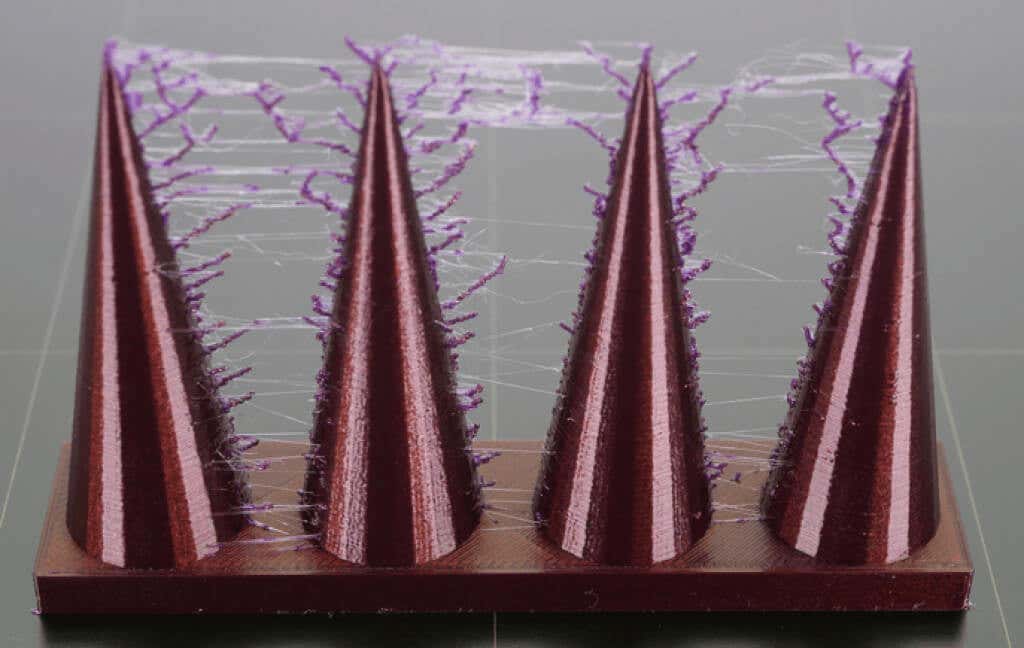

12. Stop Stringing

Also called oozing, stringing is among the most typical points that break 3D FDM prints. Skinny bits of stringy plastic type on the mannequin when the extruder strikes from one level to a different.

There are a number of elements you'll want to examine to repair this:

- Is the temperature too excessive? An overheating extruder will make the filament ooze out too shortly. Decrease the temperature by a couple of levels so it doesn’t leak out so quick.

- Improve the motion velocity. If the printer doesn’t transfer quick sufficient on its X or Y-axis, the extruder can depart skinny strings of plastic behind. Go into your slicing software program’s settings and regulate the motion velocity settings.

- Regulate the retraction velocity setting. A sluggish retraction velocity will trigger the filament to ooze via the nozzle earlier than the extruder can attain its new place. This may unfold the plastic from level A to level B like a spider net. Attempt your slicer’s software program pre-configurations and have in mind the filament materials when selecting.

3D Printing Can Be Difficult

Making a 3D mannequin is very satisfying, however plenty of issues can go flawed and it’s unattainable to cowl the whole lot in a single article. There are a lot of variables to bear in mind if you use an FDM printer, so don’t panic in case your 3D print doesn’t prove in addition to you’d hoped. Be sure your printer is correctly calibrated and that you simply’re utilizing high-quality filament. As soon as that’s out of the best way, undergo every troubleshooting step.

If nothing helps, give us extra particulars about your 3D printing points within the remark part beneath and we’ll do our greatest that can assist you out.

Post a Comment