A plastic jug is fodder for a cloth developed at Rice College that turns waste plastic into a cloth that absorbs carbon dioxide. The lab is concentrating on flue gases that now require a much more advanced course of to sequester carbon dioxide. Credit score: Jeff Fitlow/Rice College

Rice College lab turns hard-to-process trash into carbon-capture grasp.

Right here’s one other factor to do with that mountain of used plastic: make it absorb extra carbon dioxide.

What looks as if a win-win for a pair of urgent environmental issues describes a Rice College lab’s newly found chemical method to show waste plastic into an efficient carbon dioxide (CO2) sorbent for trade.

Rice chemist James Tour and co-lead authors Rice alumnus Wala Algozeeb, graduate scholar Paul Savas and postdoctoral researcher Zhe Yuan reported within the American Chemical Society journal ACS Nano that heating plastic waste within the presence of potassium acetate produced particles with nanometer-scale pores that lure carbon dioxide molecules.

These particles can be utilized to take away CO2 from flue gasoline streams, they reported.

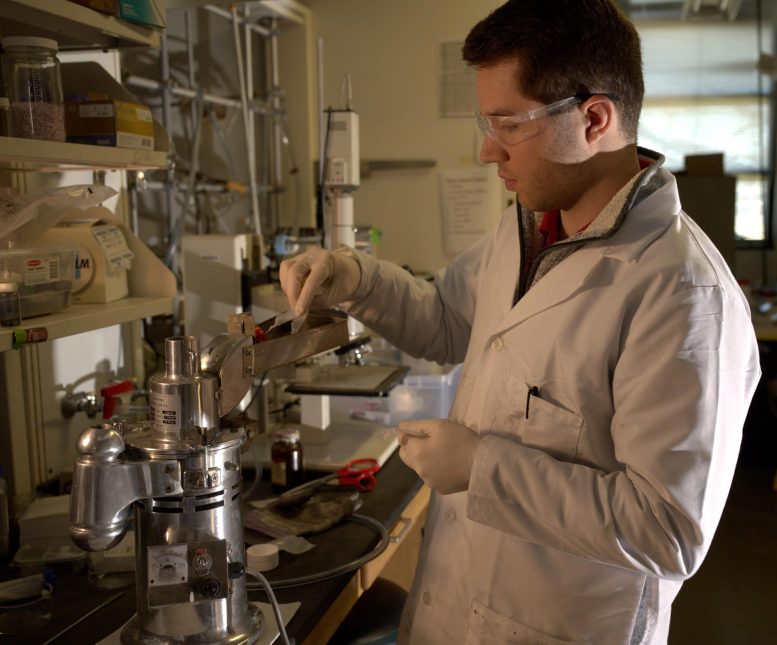

Rice College graduate scholar Paul Savas feeds uncooked plastic right into a crusher to organize it for pyrolysis, or heating in an inert ambiance. Pyrolyzing the fabric within the presence of potassium salts turns it into a cloth that sequesters carbon dioxide from flue gasoline. Credit score: Jeff Fitlow/Rice College

“Level sources of CO2 emissions like energy plant exhaust stacks will be fitted with this waste-plastic-derived materials to take away monumental quantities of CO2 that will usually fill the ambiance,” Tour mentioned. “It's a good way to have one downside, plastic waste, deal with one other downside, CO2 emissions.”

A present course of to pyrolyze plastic referred to as chemical recycling produces oils, gases and waxes, however the carbon byproduct is sort of ineffective, he mentioned. Nevertheless, pyrolyzing plastic within the presence of potassium acetate produces porous particles capable of maintain as much as 18% of their very own weight in CO2 at room temperature.

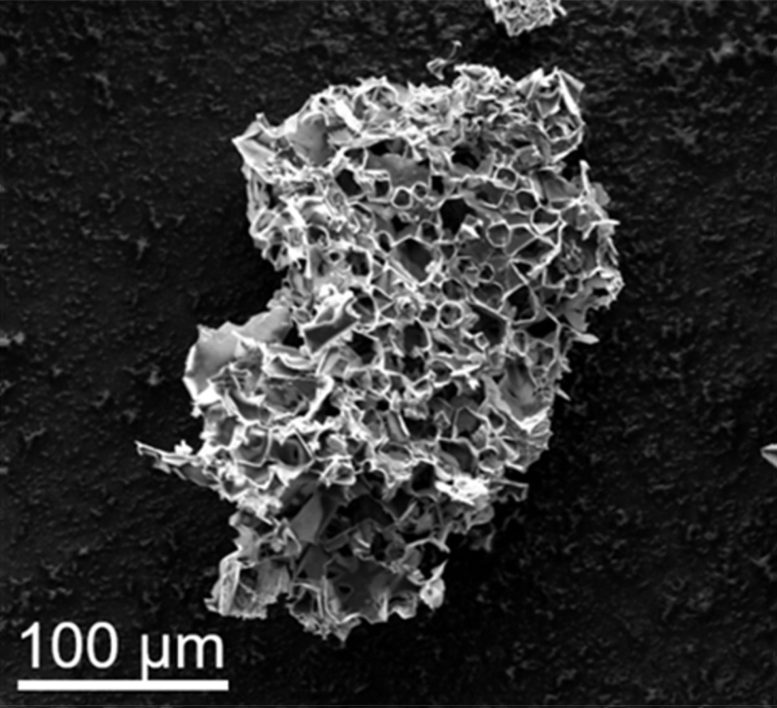

Pores on this micron-scale particle, the results of pyrolyzing within the presence of potassium acetate, are capable of sequester carbon dioxide from streams of flue gasoline. Rice College scientists say the method might be a win-win for a pair of urgent environmental issues. Credit score: Tour Group/Rice College

As well as, whereas typical chemical recycling doesn’t work for polymer wastes with low mounted carbon content material as a way to generate CO2 sorbent, together with polypropylene and high- and low-density polyethylene, the principle constituents in municipal waste, these plastics work particularly nicely for capturing CO2 when handled with potassium acetate.

The lab estimates the price of carbon dioxide seize from a degree supply like post-combustion flue gasoline could be $21 a ton, far cheaper than the energy-intensive, amine-based course of in widespread use to tug carbon dioxide from pure gasoline feeds, which prices $80-$160 a ton.

A Rice College chemist prepares to warmth plastic powder mixed with potassium acetate to show it into porous particles that take in carbon dioxide. Credit score: Jeff Fitlow/Rice College

Like amine-based supplies, the sorbent will be reused. Heating it to about 75 levels Celsius (167 levels Fahrenheit) releases trapped carbon dioxide from the pores, regenerating about 90% of the fabric’s binding websites.

As a result of it cycles at 75 levels Celsius, polyvinyl chloride vessels are adequate to interchange the costly steel vessels which might be usually required. The researchers famous the sorbent is anticipated to have an extended lifetime than liquid amines, reducing downtime as a consequence of corrosion and sludge formation.

Rice College chemists modify waste plastic to soak up carbon dioxide from flue gasoline streams extra effectively than present processes. From left: Paul Savas, James Tour and Zhe Yuan. Credit score: Jeff Fitlow/Rice College

To make the fabric, waste plastic is changed into powder, combined with potassium acetate and heated at 600 C (1,112 F) for 45 minutes to optimize the pores, most of that are about 0.7 nanometers broad. Greater temperatures led to wider pores. The method additionally produces a wax byproduct that may be recycled into detergents or lubricants, the researchers mentioned.

Reference: “Plastic Waste Product Captures Carbon Dioxide in Nanometer Pores” by Wala A. Algozeeb, Paul E. Savas, Zhe Yuan, Zhe Wang, Carter Kittrell, Jacklyn N. Corridor, Weiyin Chen, Praveen Bollini and James M. Tour, 5 April 2022, ACS Nano.

DOI: 10.1021/acsnano.2c00955

Co-authors of the paper are Rice alumnus Zhe Wang and analysis scientist Carter Kittrell, and graduate scholar Jacklyn Corridor and Praveen Bollini, an assistant professor of chemical and biomolecular engineering, each of the College of Houston. Tour is the T.T. and W.F. Chao Chair in Chemistry in addition to a professor of supplies science and nanoengineering.

The Division of Power (DE-F0031794) and Saudi Aramco supported the analysis.

Post a Comment