A brand new method may allow a robotic to control squishy objects like pizza dough or gentle supplies like clothes.

Think about a pizza maker working with a ball of dough. She would possibly use a spatula to raise the dough onto a chopping board then use a rolling pin to flatten it right into a circle. Simple, proper? Not if this pizza maker is a robotic.

For a robotic, working with a deformable object like dough is hard as a result of the form of dough can change in some ways, that are tough to symbolize with an equation. Plus, creating a brand new form out of that dough requires a number of steps and using totally different instruments. It's particularly tough for a robotic to study a manipulation activity with an extended sequence of steps — the place there are various alternatives — since studying usually happens via trial and error.

Researchers at MIT, Carnegie Mellon College, and the College of California at San Diego, have give you a greater method. They created a framework for a robotic manipulation system that makes use of a two-stage studying course of, which may allow a robotic to carry out advanced dough-manipulation duties over an extended timeframe. A “trainer” algorithm solves every step the robotic should take to finish the duty. Then, it trains a “scholar” machine-learning mannequin that learns summary concepts about when and the best way to execute every ability it wants through the activity, like utilizing a rolling pin. With this information, the system causes about the best way to execute the talents to finish your complete activity.

The researchers present that this methodology, which they name DiffSkill, can carry out advanced manipulation duties in simulations, like chopping and spreading dough, or gathering items of dough from round a chopping board, whereas outperforming different machine-learning strategies.

Researchers from MIT and elsewhere have created a framework that might allow a robotic to successfully full advanced manipulation duties with deformable objects, like dough or fabric, that require many instruments and take a very long time to finish. Credit score: Pictures courtesy of the researchers

Past pizza-making, this methodology might be utilized in different settings the place a robotic wants to control deformable objects, similar to a caregiving robotic that feeds, bathes, or clothes somebody aged or with motor impairments.

“This methodology is nearer to how we as people plan our actions. When a human does a long-horizon activity, we're not writing down all the small print. We've a higher-level planner that roughly tells us what the levels are and a number of the intermediate targets we have to obtain alongside the best way, after which we execute them,” says Yunzhu Li, a graduate scholar within the Pc Science and Synthetic Intelligence Laboratory (CSAIL), and creator of a paper presenting DiffSkill.

Li’s co-authors embrace lead creator Xingyu Lin, a graduate scholar at Carnegie Mellon College (CMU); Zhiao Huang, a graduate scholar on the College of California at San Diego; Joshua B. Tenenbaum, the Paul E. Newton Profession Improvement Professor of Cognitive Science and Computation within the Division of Mind and Cognitive Sciences at MIT and a member of CSAIL; David Held, an assistant professor at CMU; and senior creator Chuang Gan, a analysis scientist on the MIT-IBM Watson AI Lab. The analysis will probably be offered on the Worldwide Convention on Studying Representations.

Pupil and trainer

The “trainer” within the DiffSkill framework is a trajectory optimization algorithm that may resolve short-horizon duties, the place an object’s preliminary state and goal location are shut collectively. The trajectory optimizer works in a simulator that fashions the physics of the actual world (often called a differentiable physics simulator, which places the “Diff” in “DiffSkill”). The “trainer” algorithm makes use of the data within the simulator to find out how the dough should transfer at every stage, one by one, after which outputs these trajectories.

Then the “scholar” neural community learns to mimic the actions of the trainer. As inputs, it makes use of two digicam pictures, one displaying the dough in its present state and one other displaying the dough on the finish of the duty. The neural community generates a high-level plan to find out the best way to hyperlink totally different expertise to achieve the aim. It then generates particular, short-horizon trajectories for every ability and sends instructions on to the instruments.

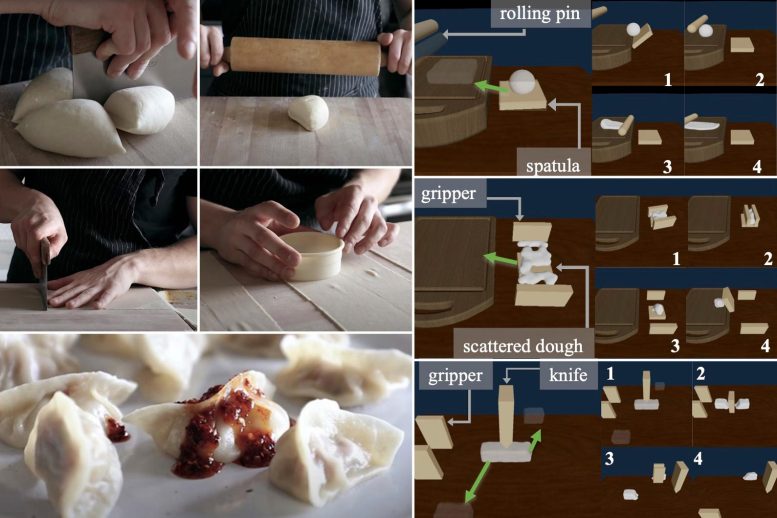

The researchers used this system to experiment with three totally different simulated dough-manipulation duties. In a single activity, the robotic makes use of a spatula to raise dough onto a chopping board then makes use of a rolling pin to flatten it. In one other, the robotic makes use of a gripper to collect dough from all around the counter, locations it on a spatula, and transfers it to a chopping board. Within the third activity, the robotic cuts a pile of dough in half utilizing a knife after which makes use of a gripper to move each bit to totally different areas.

Researchers developed a robotic manipulation system can carry out advanced dough manipulation duties with instruments in simulations, like gathering dough and inserting it onto a chopping board (left), chopping a bit of dough in half and separating the halves (middle), and lifting dough onto a chopping board then flattening it with a rolling pin (proper). Their method is ready to carry out these duties efficiently, whereas different machine studying strategies fail. Credit score: MIT

A minimize above the remaining

DiffSkill was in a position to outperform in style methods that depend on reinforcement studying, the place a robotic learns a activity via trial and error. Actually, DiffSkill was the one methodology that was in a position to efficiently full all three dough manipulation duties. Apparently, the researchers discovered that the “scholar” neural community was even in a position to outperform the “trainer” algorithm, Lin says.

“Our framework gives a novel method for robots to amass new expertise. These expertise can then be chained to resolve extra advanced duties that are past the aptitude of earlier robotic techniques,” says Lin.

As a result of their methodology focuses on controlling the instruments (spatula, knife, rolling pin, and many others.) it might be utilized to totally different robots, however provided that they use the precise instruments the researchers outlined. Sooner or later, they plan to combine the form of a instrument into the reasoning of the “scholar” community so it might be utilized to different tools.

The researchers intend to enhance the efficiency of DiffSkill through the use of 3D information as inputs, as an alternative of pictures that may be tough to switch from simulation to the actual world. Additionally they need to make the neural community planning course of extra environment friendly and gather extra numerous coaching information to boost DiffSkill’s potential to generalize to new conditions. In the long term, they hope to use DiffSkill to extra numerous duties, together with fabric manipulation.

Reference: “Diffskill: Ability Abstraction From Differentiable Physics for Deformable Object Manipulations With Instruments” by Xingyu Lin, Zhiao Huang, Yunzhu Li, Joshua B. Tenenbaum, David Held and Chuang Gan.

OpenReview

This work is supported, partially, by the Nationwide Science Basis, LG Electronics, the MIT-IBM Watson AI Lab, the Workplace of Naval Analysis, and the Protection Superior Analysis Tasks Company Machine Frequent Sense program.

Post a Comment