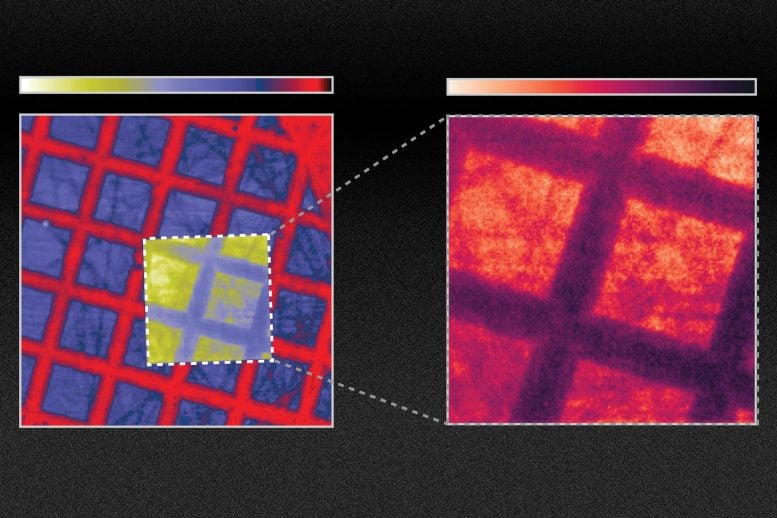

Researchers at MIT have proven how one may enhance the effectivity of scintillators by at the least tenfold by altering the fabric’s floor. This picture reveals a TEM grid on scotch tape, with the appropriate facet exhibiting the scene after it's corrected. Credit score: Picture courtesy of Charles Roques-Carmes, Nicholas Rivera, Marin Soljacic, Steven Johnson, and John Joannopoulos, et al.

Enhancements within the materials that converts X-rays into gentle, for medical or industrial photographs, may enable a tenfold sign enhancement.

Scintillators are supplies that emit gentle when bombarded with high-energy particles or X-rays. In medical or dental X-ray programs, they convert incoming X-ray radiation into seen gentle that may then be captured utilizing movie or photosensors. They’re additionally used for night-vision programs and for analysis, comparable to in particle detectors or electron microscopes.

Researchers at MIT have now proven how one may enhance the effectivity of scintillators by at the least tenfold, and even perhaps a hundredfold, by altering the fabric’s floor to create sure nanoscale configurations, comparable to arrays of wave-like ridges. Whereas previous makes an attempt to develop extra environment friendly scintillators have targeted on discovering new supplies, the brand new method may in precept work with any of the prevailing supplies.

Although it's going to require extra effort and time to combine their scintillators into present X-ray machines, the group believes that this methodology may result in enhancements in medical diagnostic X-rays or CT scans, to cut back dose publicity and enhance picture high quality. In different functions, comparable to X-ray inspection of manufactured components for high quality management, the brand new scintillators may allow inspections with greater accuracy or at quicker speeds.

The findings are described within the journal Science, in a paper by MIT doctoral college students Charles Roques-Carmes and Nicholas Rivera; MIT professors Marin Soljacic, Steven Johnson, and John Joannopoulos; and 10 others.

Whereas scintillators have been in use for some 70 years, a lot of the analysis within the subject has targeted on creating new supplies that produce brighter or quicker gentle emissions. The brand new method as a substitute applies advances in nanotechnology to present supplies. By creating patterns in scintillator supplies at a size scale similar to the wavelengths of the sunshine being emitted, the group discovered that it was doable to dramatically change the fabric’s optical properties.

To make what they coined “nanophotonic scintillators,” Roques-Carmes says, “you possibly can immediately make patterns contained in the scintillators, or you possibly can glue on one other materials that might have holes on the nanoscale. The specifics rely on the precise construction and materials.” For this analysis, the group took a scintillator and made holes spaced aside by roughly one optical wavelength, or about 500 nanometers (billionths of a meter).

“The important thing to what we’re doing is a basic principle and framework now we have developed,” Rivera says. This enables the researchers to calculate the scintillation ranges that might be produced by any arbitrary configuration of nanophotonic constructions. The scintillation course of itself entails a sequence of steps, making it difficult to unravel. The framework the group developed entails integrating three several types of physics, Roques-Carmes says. Utilizing this technique they've discovered a very good match between their predictions and the outcomes of their subsequent experiments.

The experiments confirmed a tenfold enchancment in emission from the handled scintillator. “So, that is one thing that may translate into functions for medical imaging, that are optical photon-starved, that means the conversion of X-rays to optical gentle limits the picture high quality. [In medical imaging,] you do not need to irradiate your sufferers with an excessive amount of of the X-rays, particularly for routine screening, and particularly for younger sufferers as effectively,” Roques-Carmes says.

“We consider that it will open a brand new subject of analysis in nanophotonics,” he provides. “You need to use loads of the prevailing work and analysis that has been accomplished within the subject of nanophotonics to enhance considerably on present supplies that scintillate.”

Soljacic says that whereas their experiments proved a tenfold enchancment in emission might be achieved, by additional fine-tuning the design of the nanoscale patterning, “we additionally present you can stand up to 100 occasions [improvement], and we consider we even have a path towards making it even higher,” he says.

Soljacic factors out that in different areas of nanophotonics, a subject that offers with how gentle interacts with supplies which might be structured on the nanometer scale, the event of computational simulations has enabled speedy, substantial enhancements, for instance within the growth of photo voltaic cells and LEDs. The brand new fashions this group developed for scintillating supplies may facilitate related leaps on this expertise, he says.

Nanophotonics methods “provide the final energy of tailoring and enhancing the conduct of sunshine,” Soljacic says. “However till now, this promise, this potential to do that with scintillation was unreachable as a result of modeling the scintillation was very difficult. Now, this work for the primary time opens up this subject of scintillation, absolutely opens it, for the appliance of nanophotonics methods.” Extra usually, the group believes that the mix of nanophotonic and scintillators may in the end allow greater decision, decreased X-ray dose, and energy-resolved X-ray imaging.

Yablonovitch provides that whereas the idea nonetheless must be confirmed in a sensible machine, he says that, “After years of analysis on photonic crystals in optical communication and different fields, it’s lengthy overdue that photonic crystals must be utilized to scintillators, that are of nice sensible significance but have been missed” till this work.

Reference: 24 February 2022, Science.

DOI: 10.1126/science.abm9293

The analysis group included Ali Ghorashi, Steven Kooi, Yi Yang, Zin Lin, Justin Beroz, Aviram Massuda, Jamison Sloan, and Nicolas Romeo at MIT; Yang Yu at Raith America, Inc.; and Ido Kaminer at Technion in Israel. The work was supported, partly, by the U.S. Military Analysis Workplace and the U.S. Military Analysis Laboratory by the Institute for Soldier Nanotechnologies, by the Air Drive Workplace of Scientific Analysis, and by a Mathworks Engineering Fellowship.

Post a Comment