A newly created nano-architected materials reveals a property that beforehand was simply theoretically doable: it will possibly refract gentle backward, whatever the angle at which the sunshine strikes the fabric.

This property is named unfavourable refraction and it implies that the refractive index—the velocity that gentle can journey by means of a given materials—is unfavourable throughout a portion of the electromagnetic spectrum in any respect angles.

Refraction is a typical property in supplies; consider the way in which a straw in a glass of water seems shifted to the aspect, or the way in which lenses in eyeglasses focus gentle. However unfavourable refraction doesn't simply contain shifting gentle a number of levels to 1 aspect. Quite, the sunshine is distributed in an angle utterly reverse from the one at which it entered the fabric. This has not been noticed in nature however, starting within the Sixties, was theorized to happen in so-called artificially periodic supplies—that's, supplies constructed to have a selected structural sample. Solely now have fabrication processes have caught as much as principle to make unfavourable refraction a actuality.

“Unfavourable refraction is essential to the way forward for nanophotonics, which seeks to know and manipulate the habits of sunshine when it interacts with supplies or strong buildings on the smallest doable scales,” says Julia R. Greer, Caltech’s Ruben F. and Donna Mettler Professor of Supplies Science, Mechanics and Medical Engineering, and one of many senior authors of a paper describing the brand new materials. The paper was printed within the journal Nano Letters.

The brand new materials achieves its uncommon property by means of a mixture of group on the nano- and microscale and the addition of a coating of a skinny metallic germanium movie by means of a time- and labor-intensive course of. Greer is a pioneer within the creation of such nano-architected supplies, or supplies whose construction is designed and arranged at a nanometer scale and that consequently exhibit uncommon, usually shocking properties—for instance, exceptionally light-weight ceramics that spring again to their unique form, like a sponge, after being compressed.

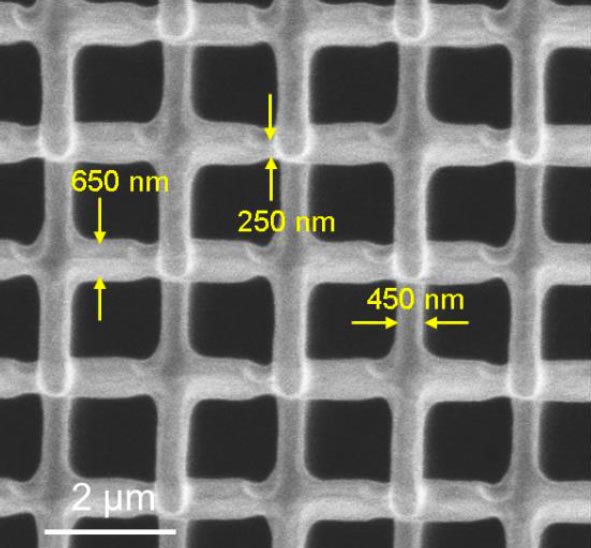

Beneath an electron microscope, the brand new materials’s construction resembles a lattice of hole cubes. Every dice is so tiny that the width of the beams making up the dice’s construction is 100 occasions smaller than the width of a human hair. The lattice was constructed utilizing a polymer materials, which is comparatively simple to work with in 3-D printing, after which coated with the metallic germanium.

“The mixture of the construction and the coating give the lattice this uncommon property,” says Ryan Ng (MS ’16, PhD ’20), corresponding creator of the Nano Letters paper. Ng carried out this analysis whereas a graduate scholar in Greer’s lab and is now a postdoctoral researcher on the Catalan Institute of Nanoscience and Nanotechnology in Spain. The analysis group zeroed in on the cube-lattice construction and materials as the correct mixture by means of a painstaking pc modeling course of (and the data that geranium is a high-index materials).

To get the polymer coated evenly at that scale with a metallic required the analysis group to develop a completely new methodology. In the long run, Ng, Greer, and their colleagues used a sputtering approach during which a disk of germanium was bombarded with high-energy ions that blasted germanium atoms off of the disk and onto the floor of the polymer lattice. “It isn’t simple to get a good coating,” Ng says. “It took a very long time and numerous effort to optimize this course of.”

The expertise has potential purposes for telecommunications, medical imaging, radar camouflaging, and computing.

In a 1965 commentary, Caltech alumnus Gordon Moore (PhD ’54), a life member of the Caltech Board of Trustees, predicted that built-in circuits would get twice as sophisticated and half as costly each two years. Nonetheless, due to the elemental limits on energy dissipation and transistor density allowed by present silicon semiconductors, the scaling predicted by Moore’s Regulation ought to quickly finish. “We’re reaching the tip of our capability to comply with Moore’s Regulation; making digital transistors as small as they'll go,” Ng says. The present work is a step in the direction of demonstrating optical properties that may be required to allow 3-D photonic circuits. As a result of gentle strikes rather more rapidly than electrons, 3-D photonic circuits, in principle, can be a lot quicker than conventional ones.

Reference: “Dispersion Mapping in 3-Dimensional Core–Shell Photonic Crystal Lattices Able to Unfavourable Refraction within the Mid-Infrared” by Victoria F. Chernow, Ryan C. Ng, Siying Peng, Harry A. Atwater and Julia R. Greer, 21 October 2022, Nano Letters.

DOI: 10.1021/acs.nanolett.1c02851

Coauthors embody Harry Atwater, the Howard Hughes Professor of Utilized Physics and Supplies Science and Otis Sales space Management Chair of the Division of Engineering and Utilized Science; Victoria F. Chernow (PhD ’17) and Siying Peng (PhD ’17). This analysis as funded by the Dow-Resnick Grant, the Protection Superior Analysis Tasks Company (DARPA), and the U.S. Division of Power (DOE) Workplace of Science.

Post a Comment