Inventory video as an example the idea of a brilliant sturdy cellular phone.

The brand new substance is the results of a feat regarded as unimaginable: polymerizing a fabric in two dimensions.

Utilizing a novel polymerization course of, MIT chemical engineers have created a brand new materials that's stronger than metal and as mild as plastic, and could be simply manufactured in giant portions.

The brand new materials is a two-dimensional polymer that self-assembles into sheets, in contrast to all different polymers, which type one-dimensional, spaghetti-like chains. Till now, scientists had believed it was unimaginable to induce polymers to type 2D sheets.

Such a fabric could possibly be used as a light-weight, sturdy coating for automotive components or cell telephones, or as a constructing materials for bridges or different constructions, says Michael Strano, the Carbon P. Dubbs Professor of Chemical Engineering at MIT and the senior writer of the brand new research.

“We don’t normally consider plastics as being one thing that you can use to assist a constructing, however with this materials, you possibly can allow new issues,” he says. “It has very uncommon properties and we’re very enthusiastic about that.”

The researchers have filed for 2 patents on the method they used to generate the fabric, which they describe in a paper printed in Nature on February 2, 2022. MIT postdoc Yuwen Zeng is the lead writer of the research.

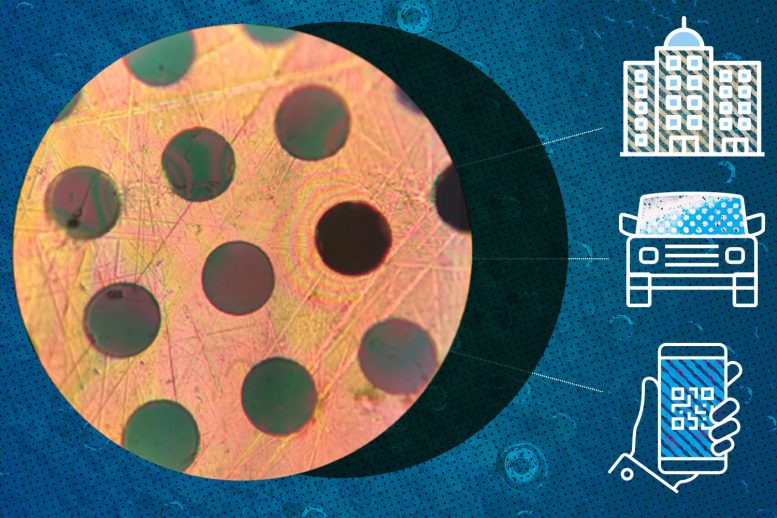

The brand new materials is a two-dimensional polymer that self-assembles into sheets and could possibly be used as a light-weight, sturdy coating for automotive components or cell telephones, or as a constructing materials for bridges or different constructions. Credit score: polymer movie courtesy of the researchers; Christine Daniloff, MIT

Two dimensions

Polymers, which embody all plastics, include chains of constructing blocks known as monomers. These chains develop by including new molecules onto their ends. As soon as fashioned, polymers could be formed into three-dimensional objects, reminiscent of water bottles, utilizing injection molding.

Polymer scientists have lengthy hypothesized that if polymers could possibly be induced to develop right into a two-dimensional sheet, they need to type extraordinarily sturdy, light-weight supplies. Nonetheless, many many years of labor on this subject led to the conclusion that it was unimaginable to create such sheets. One motive for this was that if only one monomer rotates up or down, out of the aircraft of the rising sheet, the fabric will start increasing in three dimensions and the sheet-like construction will probably be misplaced.

Nonetheless, within the new research, Strano and his colleagues got here up with a brand new polymerization course of that permits them to generate a two-dimensional sheet known as a polyaramide. For the monomer constructing blocks, they use a compound known as melamine, which comprises a hoop of carbon and nitrogen atoms. Beneath the correct circumstances, these monomers can develop in two dimensions, forming disks. These disks stack on high of one another, held collectively by hydrogen bonds between the layers, which make the construction very secure and robust.

“As a substitute of creating a spaghetti-like molecule, we will make a sheet-like molecular aircraft, the place we get molecules to hook themselves collectively in two dimensions,” Strano says. “This mechanism occurs spontaneously in answer, and after we synthesize the fabric, we will simply spin-coat skinny movies which can be terribly sturdy.”

As a result of the fabric self-assembles in answer, it may be made in giant portions by merely rising the amount of the beginning supplies. The researchers confirmed that they may coat surfaces with movies of the fabric, which they name 2DPA-1.

“With this advance, we now have planar molecules which can be going to be a lot simpler to trend into a really sturdy, however extraordinarily skinny materials,” Strano says.

Mild however sturdy

The researchers discovered that the brand new materials’s elastic modulus — a measure of how a lot power it takes to deform a fabric — is between 4 and 6 instances better than that of bulletproof glass. In addition they discovered that its yield power, or how a lot power it takes to interrupt the fabric, is twice that of metal, despite the fact that the fabric has solely about one-sixth the density of metal.

Matthew Tirrell, dean of the Pritzker College of Molecular Engineering on the College of Chicago, says that the brand new approach “embodies some very artistic chemistry to make these bonded 2D polymers.”

“An vital side of those new polymers is that they're readily processable in answer, which is able to facilitate quite a few new functions the place excessive power to weight ratio is vital, reminiscent of new composite or diffusion barrier supplies,” says Tirrell, who was not concerned within the research.

One other key function of 2DPA-1 is that it's impermeable to gases. Whereas different polymers are constituted of coiled chains with gaps that permit gases to seep by means of, the brand new materials is constituted of monomers that lock collectively like LEGOs, and molecules can't get between them.

“This might permit us to create ultrathin coatings that may fully forestall water or gases from getting by means of,” Strano says. “This type of barrier coating could possibly be used to guard metallic in vehicles and different autos, or metal constructions.”

Strano and his college students at the moment are finding out in additional element how this specific polymer is ready to type 2D sheets, and they're experimenting with altering its molecular make-up to create different kinds of novel supplies.

Reference: “Irreversible synthesis of an ultrastrong two-dimensional polymeric materials” by Yuwen Zeng, Pavlo Gordiichuk, Takeo Ichihara, Ge Zhang, Emil Sandoz-Rosado, Eric D. Wetzel, Jason Tresback, Jing Yang, Daichi Kozawa, Zhongyue Yang, Matthias Kuehne, Michelle Quien, Zhe Yuan, Xun Gong, Guangwei He, Daniel James Lundberg, Pingwei Liu, Albert Tianxiang Liu, Jing Fan Yang, Heather J. Kulik and Michael S. Strano, 2 February 2022, Nature.

DOI: 10.1038/s41586-021-04296-3

The analysis was funded by the Middle for Enhanced Nanofluidic Transport (CENT) an Power Frontier Analysis Middle sponsored by the U.S. Division of Power Workplace of Science, and the Military Analysis Laboratory.

Post a Comment