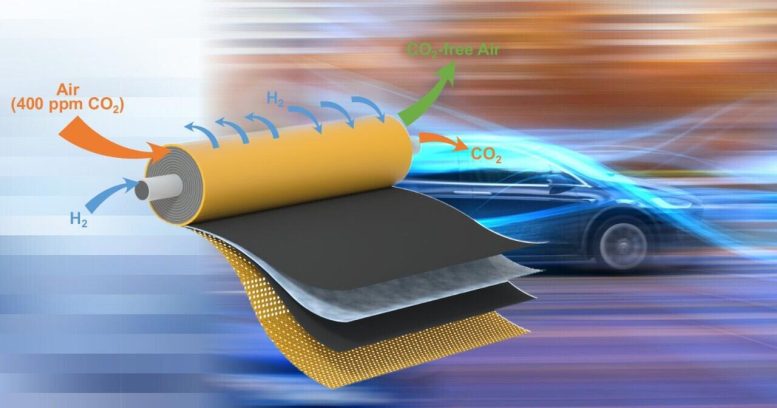

College of Delaware researchers have damaged new floor that might deliver extra environmentally pleasant gas cells nearer to commercialization. Credit score: Graphic illustration by Jeffrey C. Chase

College of Delaware researchers’ carbon seize advance might deliver environmentally pleasant gas cells nearer to market.

College of Delaware engineers have demonstrated a approach to successfully seize 99% of carbon dioxide from air utilizing a novel electrochemical system powered by hydrogen.

It's a important advance for carbon dioxide seize and will deliver extra environmentally pleasant gas cells nearer to market.

The analysis crew, led by UD Professor Yushan Yan, reported their technique in Nature Power on Thursday, February 3.

Recreation-changing tech for gas cell effectivity

Gasoline cells work by changing gas chemical power straight into electrical energy. They can be utilized in transportation for issues like hybrid or zero-emission automobiles.

Yan, Henry Belin du Pont Chair of Chemical and Biomolecular Engineering, has been working for a while to enhance hydroxide trade membrane (HEM) gas cells, a cheap and environmentally pleasant different to conventional acid-based gas cells used right this moment.

However HEM gas cells have a shortcoming that has stored them off the street — they're extraordinarily delicate to carbon dioxide within the air. Primarily, the carbon dioxide makes it exhausting for a HEM gas cell to breathe.

This defect rapidly reduces the gas cell’s efficiency and effectivity by as much as 20%, rendering the gas cell no higher than a gasoline engine. Yan’s analysis group has been trying to find a workaround for this carbon dioxide conundrum for over 15 years.

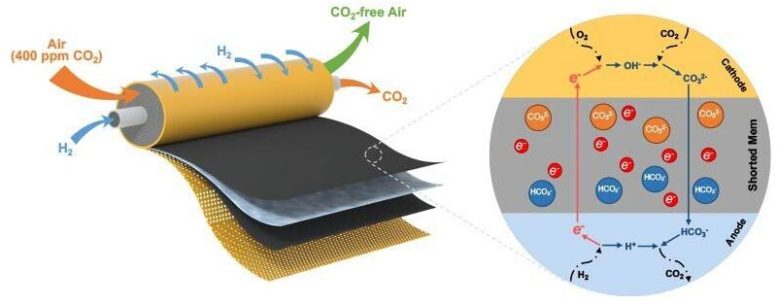

The UD analysis crew’s spiral wound module takes in hydrogen and air via two separate inlets (proven on the left) and emits carbon dioxide and carbon dioxide-free air (proven on the appropriate) after passing via two large-area, catalyst-coated shorted membranes. The inset picture on the appropriate reveals, partly, how the molecules transfer throughout the short-circuited membrane. Credit score: College of Delaware

Just a few years again, the researchers realized this drawback would possibly really be an answer — for carbon dioxide removing.

“As soon as we dug into the mechanism, we realized the gas cells had been capturing nearly each little bit of carbon dioxide that got here into them, they usually had been actually good at separating it to the opposite facet,” stated Brian Setzler, assistant professor for analysis in chemical and biomolecular engineering and paper co-author.

Whereas this isn’t good for the gas cell, the crew knew if they might leverage this built-in “self-purging” course of in a separate machine upstream from the gas cell stack, they might flip it right into a carbon dioxide separator.

“It seems our method could be very efficient. We will seize 99% of the carbon dioxide out of the air in a single go if we've the appropriate design and proper configuration,” stated Yan.

So, how did they do it?

They discovered a approach to embed the ability supply for the electrochemical know-how contained in the separation membrane. The method concerned internally short-circuiting the machine.

“It’s dangerous, however we managed to manage this short-circuited gas cell by hydrogen. And through the use of this inside electrically shorted membrane, we had been in a position to do away with the cumbersome parts, similar to bipolar plates, present collectors or any electrical wires sometimes present in a gas cell stack,” stated Lin Shi, a doctoral candidate within the Yan group and the paper’s lead creator.

Now, the analysis crew had an electrochemical machine that seemed like a traditional filtration membrane made for separating out gases, however with the potential to constantly choose up minute quantities of carbon dioxide from the air like a extra sophisticated electrochemical system.

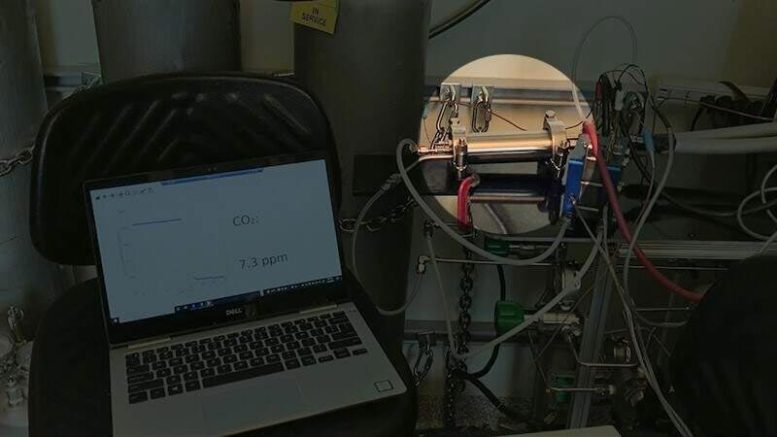

This image reveals the electrochemical system developed by the Yan group. Contained in the highlighted cylindrical metallic housing proven is the analysis crew’s novel spiral wound module. As hydrogen is fed to the machine, it powers the carbon dioxide removing course of. Pc software program on the laptop computer plots the carbon dioxide focus within the air after passing via the module. Credit score: College of Delaware

In impact, embedding the machine’s wires contained in the membrane created a short-cut that made it simpler for the carbon dioxide particles to journey from one facet to the opposite. It additionally enabled the crew to assemble a compact, spiral module with a big floor space in a small quantity. In different phrases, they now have a smaller package deal able to filtering better portions of air at a time, making it each efficient and cost-effective for gas cell functions. In the meantime, fewer parts imply much less price and, extra importantly, supplied a approach to simply scale up for the market.

The analysis crew’s outcomes confirmed that an electrochemical cell measuring 2 inches by 2 inches might constantly take away about 99% of the carbon dioxide present in air flowing at a charge of roughly two liters per minute. An early prototype spiral machine in regards to the dimension of a 12-ounce soda can is able to filtering 10 liters of air per minute and scrubbing out 98% of the carbon dioxide, the researchers stated.

Scaled for an automotive utility, the machine can be roughly the scale of a gallon of milk, Setzer stated, however the machine may very well be used to take away carbon dioxide elsewhere, too. For instance, the UD-patented know-how might allow lighter, extra environment friendly carbon dioxide removing units in spacecraft or submarines, the place ongoing filtration is crucial.

“We have now some concepts for a long-term roadmap that may actually assist us get there,” stated Setzler.

In line with Shi, for the reason that electrochemical system is powered by hydrogen, because the hydrogen economic system develops, this electrochemical machine may be utilized in airplanes and buildings the place air recirculation is desired as an energy-saving measure. Later this month, following his dissertation protection, Shi will be a part of Versogen, a UD spinoff firm based by Yan, to proceed advancing analysis towards sustainable inexperienced hydrogen.

Reference: “A shorted membrane electrochemical cell powered by hydrogen to take away CO2 from the air feed of hydroxide trade membrane gas cells” by Lin Shi, Yun Zhao, Stephanie Matz, Shimshon Gottesfeld, Brian P. Setzler and Yushan Yan, 3 February 2022, Nature Power.

DOI: 10.1038/s41560-021-00969-5

Co-authors on the paper from the Yan lab embrace Yun Zhao, co-first creator and analysis affiliate, who carried out experimental work important for testing the machine; Stephanie Matz, a doctoral scholar who contributed to the designing and fabrication of the spiral module, and Shimshon Gottesfeld, an adjunct professor of chemical and biomolecular engineering at UD. Gottesfeld was principal investigator on the 2019 undertaking, funded by the Superior Analysis Tasks Company-Power (ARPA-E), that led to the findings.

Post a Comment