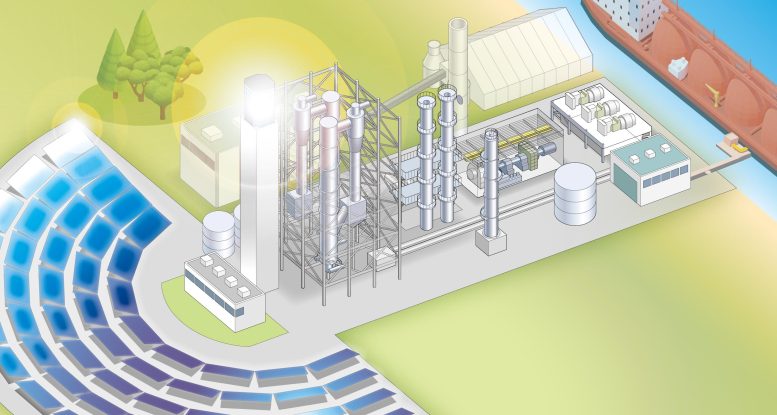

Proposed facility design for solar-powered zero-carbon emission hydrogen manufacturing. Credit score: KyotoU/Shutaro Takeda

Within the international race to curb local weather change and scale back carbon emissions, hydrogen is taken into account a critical contender to interchange fossil fuels. Though hydrogen ‘burns’ cleanly, with solely water as a by-product, the present method of creating hydrogen a dependable gas various is energy- and carbon-intensive.

Whether or not water is cut up with electrical energy or hydrogen is launched from fossil fuels or different hydrocarbon sources, each step ahead in making hydrogen is accompanied by at the very least two steps again by way of related CO2 emissions. In some processes, each kilogram of hydrogen is accompanied by virtually 30 kilograms of CO2 output.

Now, a Kyoto College-led staff of worldwide researchers has developed a novel hydrogen plant design that pulls on totally renewable assets to provide the bottom quantity of related CO2 reported thus far. They've revealed their proposal within the Worldwide Journal of Hydrogen Vitality.

“Photo voltaic power is the plain candidate for driving any hydrogen manufacturing, however the issue has usually been that daylight is just too intermittent,” says creator Shutaro Takeda.

The staff’s novel strategy of utilizing photo voltaic heating to gasify biomass appears to be the simplest and sensible method of creating hydrogen with a low carbon footprint. They're engaged on combining two completely different programs to create a brand new sort of hydrogen facility known as the solar-driven superior biomass indirect-gasification hydrogen manufacturing plant, or SABI-Hydrogen plant.

First, to successfully seize daylight, they selected an association of particular mirrors, known as heliostats, that focus mild onto a receiver on the high of a tower construction. Below these circumstances, a heat-transfer materials within the receiver can attain temperatures as much as 1,000 levels Celsius.

Subsequent, this warmth is transferred from the receiver to the gasifier a part of the system, the place a vessel containing wooden chips as biomass is very heated within the absence of oxygen. Fairly than burning by combustion, the wooden chips are transformed to a mix of gases containing a big proportion of hydrogen.

Alternatively, within the absence of photo voltaic heating, this gasifier is also heated conventionally by burning gas to ship warmth to the system.

Lastly, the staff assessed the general environmental impression of the design, primarily based on a global normal impression evaluation methodology, ReCiPe2016. The outcome confirmed that the SABI-Hydrogen system would solely emit 1.04 kg of CO2 per kg of hydrogen produced: the smallest worth amongst all current hydrogen manufacturing strategies.

Takeda sees nature as our best useful resource and offers us every thing we have to fight international warming. “Our modeling reveals that utilizing solar energy and biomass assets from managed forests might permit us to make hydrogen sustainably and with a low environmental impression,” he concludes.

Reference: “Low-carbon power transition with the solar and forest: Photo voltaic-driven hydrogen manufacturing from biomass” by Shutaro Takeda, Hoseok Nam and Andrew Chapman, 22 December 2021, Worldwide Journal of Hydrogen Vitality.

DOI: 10.1016/j.ijhydene.2021.11.203

Post a Comment